Quality Control

Built Right. Inspected Right. Done Right.

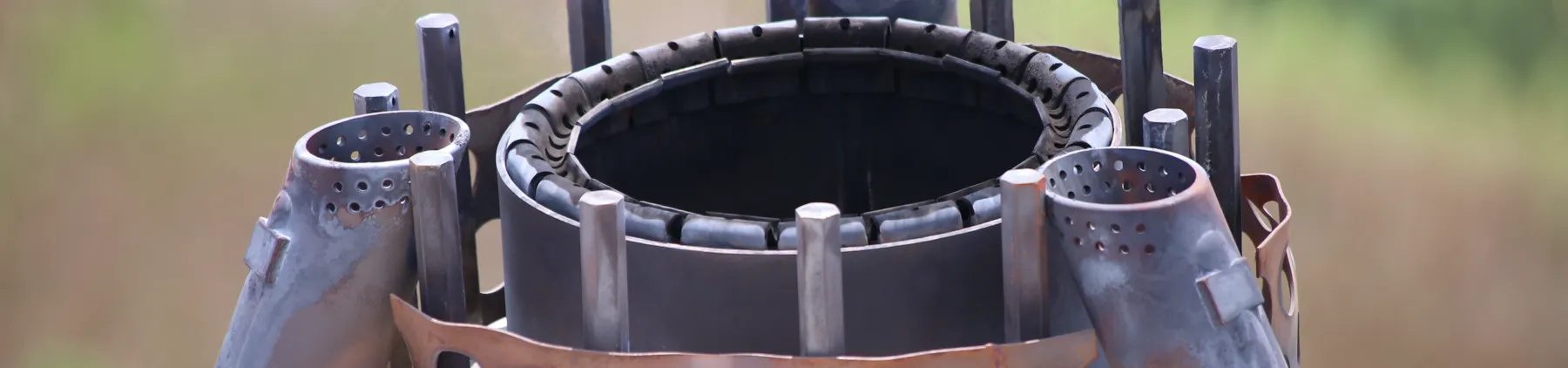

At Flares and Stacks, quality isn’t a checkpoint—it’s part of everything we do. From fabrication to field services, our Quality Control (QC) process ensures every job meets or exceeds the highest standards for safety, performance, and regulatory compliance.

We take pride in our work and back it up with detailed documentation, inspections, and verification—because in our industry, precision is non-negotiable.

What Our QC Covers

- Material Certifications & Traceability

All materials used in fabrication or repair are certified and traceable to origin. - Dimensional & Fit-Up Checks

We verify all fabricated components and assemblies before shipment or install. - Weld Inspection & Testing

Welds are visually inspected and may be tested with NDT methods as required (UT, PT, VT, etc.). - Installation Verification

Field-installed components are verified for fit, function, and alignment with system specifications. - Functional Testing

We test ignition systems, thermocouples, retractable systems, and flare pilots prior to job sign-off. - Final Reporting

All work is documented, including inspection photos, measurement logs, and compliance checklists.

Why It Matters

Ensures long-term reliability and safety

Supports OSHA, EPA, and FAA compliance

Reduces rework and downtime

Provides confidence in every install, repair, or replacement

Builds trust with your team and your regulators