NDT Inspections

See Beneath the Surface. Protect What Matters.

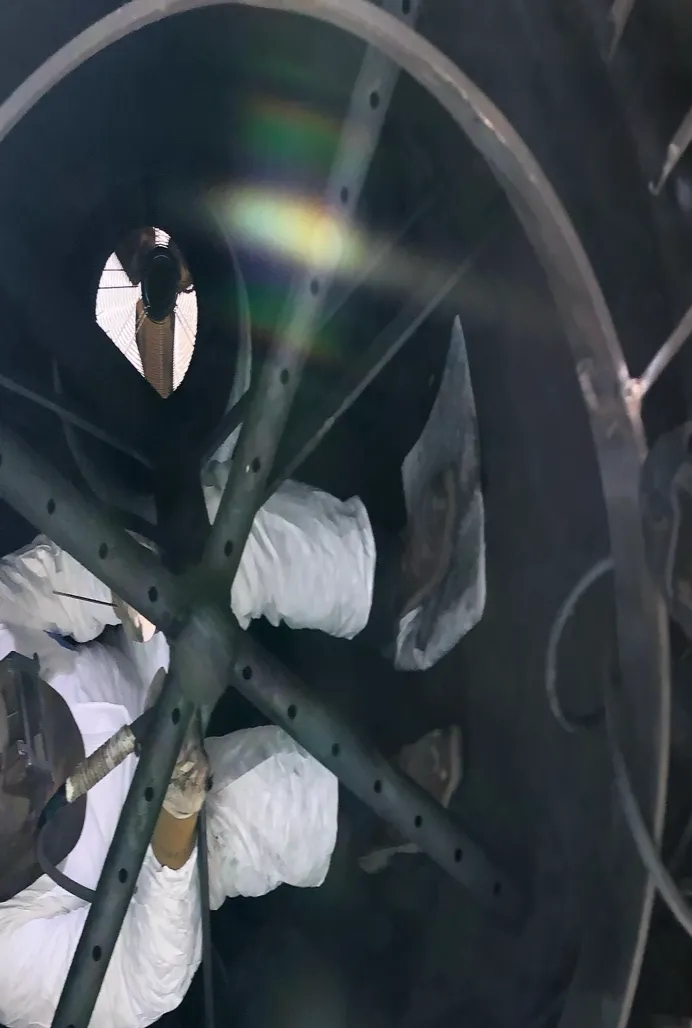

At Flares and Stacks, we offer a full range of Non-Destructive Testing (NDT) inspection services to help detect hidden flaws, ensure structural integrity, and support long-term equipment reliability. Our NDT inspections are performed by certified technicians using advanced testing methods tailored to your flare system and elevated structures.

What Is NDT?

Non-Destructive Testing (NDT) involves inspecting materials and components without causing damage. This allows you to detect problems early—before they lead to failure, shutdowns, or costly repairs.

Our NDT Capabilities Include:

- Visual Inspection (VT) – Detailed surface analysis of flare tips, stack shells, guy wires, and structural components

- Ultrasonic Testing (UT) – Internal flaw detection, wall thickness measurements

- Dye Penetrant Testing (PT) – Surface crack detection for non-porous metals

- Magnetic Rope Testing (MRT) – Specialized internal testing for guy wires

- Radiographic Testing (RT) – Available through partner labs for weld integrity

Why NDT Matters

Prevents catastrophic equipment failures

Helps meet regulatory and insurance requirements

Extends the life of flare systems

Supports safe, cost-effective maintenance planning

Provides documented condition reports for audits or capital planning

What You Get

Certified inspection report

Photos and scan data (where applicable)

Condition-based recommendations

Maintenance tracking for future planning